Successful repair of Siemens OP 17-DP Operator Panel!

March 2024

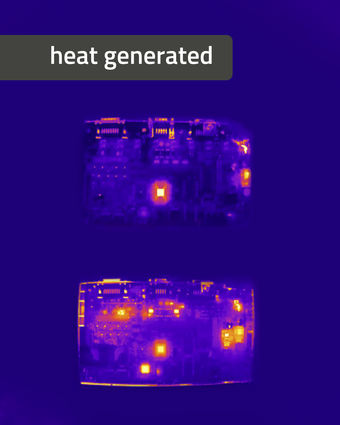

Our latest repair case: An OP 17-DP operator panel from Siemens arrived with the error message that it would not start up. After thorough analysis and the use of our thermal imaging camera, we were able to localise the problem precisely. The increased heat development was reason to a defective processor, which was also responsible for the high power consumption of the operator panel.

By replacing the processor, we were able to resolve the problem successfully. The replacement was possible without any problems as the processor did not have an internal ROM. At MakroElectronics, we repair at the component's level. Therefore, we only replace what is defective actually. This approach does not only enable a cost-efficient repair, but also ensures that your devices are ready to use as quickly as possible.

Our precise diagnosis and targeted repairs ensure that your devices function optimally. Put your trust in MakroElectronics - we'll get your technology back to peak performance!

#RepairSuccess #SiemensOP17-DP #MakroElectronics #TechnologyMaintenance

Maintenance is your save from a standstill!

January 2024

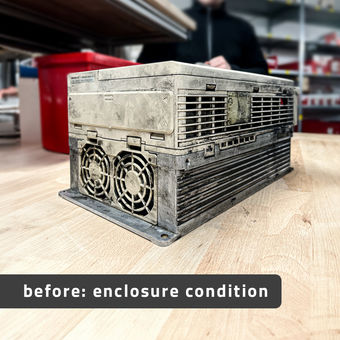

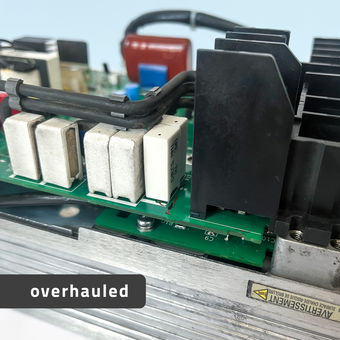

A few weeks ago, a Yaskawa V1000 inverter arrived in our repair service center and its condition was anything but in "top form". The customer realised that something was wrong and asked for an inspection. The external condition spoke for itself: a lack of maintenance had led to creeping wear and tear. The heavy soiling created a dangerous creepage point between the connection terminal and the discharge resistors of the DC link, which ultimately led to a short circuit and the destruction of the IGBT.

After intensive cleaning and the replacement of electrolytic capacitors, ceramic resistors and the IGBT, we scrutinised the Yaskawa V1000 at our test station. All functions were successfully checked and passed the test with flying colours! The frequency inverter can now be sent back to the customer.

Remember to have your devices serviced regularly, not only to prevent breakdowns, but also to ensure their optimum performance! We are happy to service and repair industrial electronics components.

#MaintenanceIsSafety #MaintenancePaysOff #YaskawaV1000 #MachineCheck #ReadyForOperation #GeneralOverhaul

Control cabinet retrofit: Our sustainable solution for the future!

October 2023

That's why we make old machines fit again:

Today we would like to tell you about an exciting project where innovation and expertise go hand in hand. A while ago, our team took on an exciting challenge: the refit of a control cabinet for a book drying system.

Why did we dare to take this step? Well, the old system was getting on in years and there were simply no spare parts left on the market. Moreover, the employees no longer have sufficient knowledge about the outdated technology. But we believe in sustainable solutions and did not want to give up on the machine!

Our main goal in this refit project was to keep the machine's proven operating concept while at the same time using the possibilities of modern technology. We designed and built the control cabinet according to the specific requirements of our customer. The automation process is carried out via a specially developed software.

The result? A book drying machine that will not only continue to function perfectly, but also offers optimised processes thanks to the new technology and software. This means not only more efficiency, but also cost savings!

We are proud to be part of this project and look forward to continuing to develop innovative solutions for our customers in the future. If you too are facing similar challenges, don't hesitate to contact us!

#ControlCabinet #Retrofit #Innovation #Sustainability #Efficiency #CostSavings #EngineeringGenius #FutureTechnology

YouZubi 2.0 in Taucha Secondary School

On 8 May, MakroElectronics took part in the career orientation fair at Taucha secondary school (Oberschule Taucha). Our colleagues presented the training programme for electronics technicians for devices and systems. A total of around 200 pupils attended the fair, with only pupils from the secondary school itself (grades 8, 9 and 10) taking part. The most frequently asked questions were about the apprenticeship, less frequently about an internship. A total of around 15 pupils approached us, which of course reflects the general decline in interest in skilled trades. The "competition" for suitable young talent will remain a challenge for skilled trades companies. That is why we would like to take part again next year and be on site to present the profession of electronics technician to practically orientated schoolchildren and get them interested in electronics. We are convinced that MakroElectronics is exactly the right place for one or two pupils to start a career with good prospects for the future.

12th Regional Training Fair Delitzsch "Training - Good for the Region"

Aktionstag Lehrstellen 2019 in Leipzig

![[Translate to EN:] MakroElectronics baut Schaltschrank Gesamtansicht](/fileadmin/_processed_/d/4/csm_Schaltschrank_1_daeda12451.jpg)

![[Translate to EN:] MakroElectronics Monteur installiert Schaltschranktechnik](/fileadmin/_processed_/0/5/csm_Schaltschrank_2_3aeae03663.jpg)

![[Translate to EN:] MakroSolutions Softwarespezialist prüft Schaltschrank Intallation](/fileadmin/_processed_/8/3/csm_Schaltschrank_4_f993c9c36c.jpg)

![[Translate to EN:] fachgerechte Kabelinstallation im Schaltschrank](/fileadmin/_processed_/b/3/csm_Schaltschrank_5_d503d40a3b.jpg)